What is Silk Screen Printing and its benefits?

17 October 2024

For nearly a century, the printing industry has utilised the accurate and traditional printing method known as silk screen printing. Serigraphy, another name for silk screen printing, has developed into a flexible process that can create eye-catching, high-quality images on a variety of surfaces and goods. It enables an array of solutions including clothing, home décor, and secure printing products. We’ll go over the process, numerous benefits, and product possibilities using this blog.

What is silk screen printing?

Silk screen printing is when you use a mesh screen to transfer ink or dye onto a substrate in a classic and very precise printing process. This is typically known as serigraphy or silk screen printing. The method involves stencils that are used to block parts where ink should not pass through, and the mesh is stretched tightly, so the pattern only goes through the parts you want. It can be constructed of nylon or polyester.

As parts of the stencil are impermeable, and parts allow ink to seep through, it can create the desired image when printing. Ink gets pushed through the mesh openings of the screen by a moving blade or squeegee across it. Following that, the ink is transferred when a reverse stroke momentarily presses the screen against the surface. The ink remains on the surface as the screen rises. For multicoloured designs, numerous screens are used since only one colour is printed at a time.

For over 100 years, silk screen printing has been used to produce patterned designs on a variety of surfaces and products, ranging from apparel to accessories. Based on Greek words for “silk” and “writing,” the word “serigraph” reflects its historical roots. It is still widely used today because of its ability to produce unique, high-quality prints, even in the face of digital printing.

Silk was originally used when screen printing, however, it is more commonly used with synthetic threads now. The screen printer can choose between stainless steel and nylon special-use mesh materials. There are several mesh sizes, which will affect how the finished design appears on the material.

How does silk screen printing work?

One common and adaptable printing technique that may be done by hand or with a machine is screen printing. Here is an explanation of the procedure:

Step 1: Design Creation

The design that you wish to print must be created first. The translucent acetate film that will be used to make the screen printing stencil is printed with this design.

Step 2: Preparing the Screen

Choose a mesh screen based on the complexity of the design and the texture of the material being printed. The screen is then coated with a light-reactive emulsion. The type of emulsion used can vary, such as Daizo, SBQ-based and dual-core emulsions.

Step 3: Exposing the Emulsion

The acetate film with the design is placed on the emulsion-coated screen. This assembly is then exposed to a bright light, which hardens the emulsion. The areas of the screen covered by the design remain in liquid form.

Step 4: Creating the Stencil

Cleaning the screen removes any remaining emulsion that hasn’t solidified after exposure and is the fourth step in the silk screen printing process. By doing so, this leaves the design with a clear imprint on the screen. After the screen has dried, any touch-ups that are required to make sure the stencil adheres to the original design are completed.

Step 5: Preparing for Print

The screen is placed on the printing press, and the material to be printed is laid flat on the printing board. In commercial settings, an automatic rotary carousel printer may be used, especially for multi-coloured designs, to ensure precise alignment and efficient printing.

Step 6: Design Application

To apply the design to your desired product or material, a squeegee is needed, either manually or mechanically. After the ink is applied to the top, this is done by driving it through the screen. When ink seeps through the stencil’s holes and onto the material or item underneath, the image is produced.

Step 7: Heat Curing and Finishing

In order to ensure a smooth and durable finish, the printed product is sent through a dryer in the last phase. After that, the product or item is submitted for cleaning and a quality check. This means that the finished product is then done and prepared for usage.

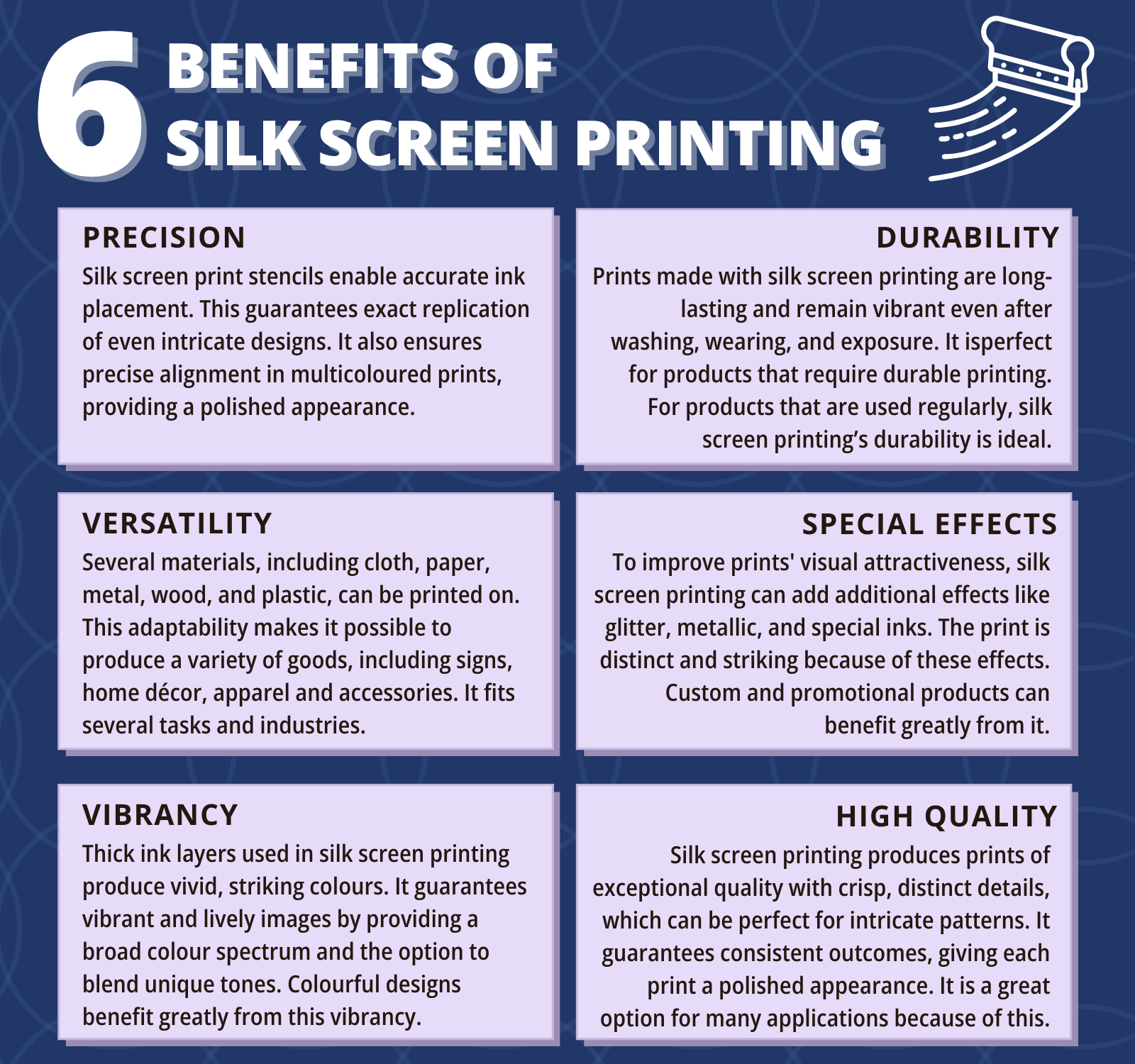

What are the benefits of silk screen printing?

What type of products can you make with silk screen printing?

Silk screen printing is a very versatile process when it comes to the great amount of things it can help to produce. It is used to create a wide variety of products, here are a few options:

Clothes: This encompasses items such as hoodies, t-shirts, jackets, tote bags, hats, scarves, and bandanas. Silk screen printing is commonly used to print graphics onto these items or patterns.

Home décor: A wide range of items for the house can be produced with silk screen printing, such as pillows, curtains, tablecloths, artwork, posters, and more. It is capable of creating great patterns for these items.

Secure printing items: silk screen printing can be used to create safely printed products including scratch-off game cards, parking permits, certificates, tickets, vouchers, and souvenir notes.

Signage: signage and displays can be popular products that are produced with the help of silk screen printing. These products can include signage, car parking signage, banners and posters, exhibition displays and more.

Using security inks with screen printing

Another important component of screen printing is the implementation and usage of security inks. These types of inks are essential for enhancing the integrity and protection of printed materials, and they are a great security feature to include when you want to deter counterfeiting and tampering. The process of screen printing allows these special inks to be perfectly embedded directly into the material, making them very hard to replicate and forge.

There are many types of inks available for screen printing, and when it comes to security inks, they each offer unique protective features. For example, UV-reactive inks become visible only under ultraviolet light, making them effective for products like tickets and certificates. Thermochromic inks change colour with heat, adding an interactive element, while optically variable inks display different colours from different angles. By using these inks in screen printing, businesses can create visually appealing products that are also well-protected against fraud.

Conclusion

The printing industry still respects and uses silk screen printing because of its exceptional accuracy, adaptability, and capacity to create vibrant, long-lasting prints. Silk screen printing has many uses, ranging from secure printed goods and signage to personalised clothing and home décor. Its continued appeal serves as proof of the excellence it brings to printed goods. Whether you want to create elaborate patterns or striking, attention-grabbing visuals, silk screen printing offers a reliable and effective option.